Logimag Bonded Magnet Manufacturer

Logimag is renowned as a leading manufacturer of bonded magnets, providing a range of high-quality magnetic products to bonded magnet supplier customers worldwide. Since its establishment, Logimag has become synonymous with excellence in magnetic material solutions, and the company has established a reputation for its exceptional product quality, innovative technologies, and reliable customer service.

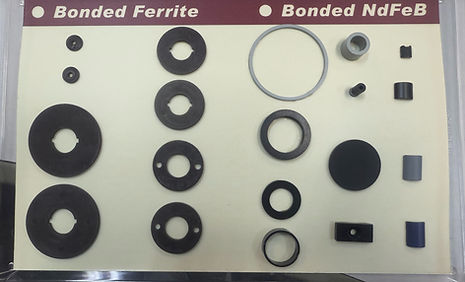

Bonded NdFeB Magnet Material Information

Bonded NdFeB (Neodymium-Iron-Boron) magnets are one of the most popular types of permanent magnets in modern industries due to their impressive magnetic properties, versatility, and cost-effectiveness. These magnets are made using advanced manufacturing techniques such as injection molding or hot pressing, which allows them to be molded into complex shapes and customized to meet the specific needs of various applications. Logimag, a leading magnet manufacturer, specializes in producing high-quality bonded NdFeB magnets with superior properties that are suitable for a wide range of industries, including automotive, electronics, medical devices, and renewable energy systems.

-

Produced by Injection Molding or Hot Pressing with Mixture of Ferrite/Rare Earth Magnet Powder & Polymer Binder

-

Complex Shapes Possible (Gears, Thin Rings, etc)

-

Reduce Assembly Time - Mold or Insert Components into Magnets during Manufacturing Process

-

Good Resistance to Chips & Corrosions

-

Excellent Corrosion Resistance

-

Magnetize Entirely or in Segments

-

Maximum Working Temperature 200℃ (Injection Bonded) / 120℃ (Compression Bonded)

What Are Bonded NdFeB Magnets?

Bonded NdFeB magnets are permanent magnets that are created by combining magnetic powders with a binder material. The most commonly used binder materials include plastic and rubber compounds, which help form a cohesive material when the magnetic powder is combined with them. Bonded neodymium magnets can be produced through various processes such as injection molding, compression bonding, and extrusion. These bonded NdFeB magnets are known for their flexibility, lightweight, and ability to be molded into complex shapes, which makes them suitable for a wide range of applications. Bonded magnets, especially those manufactured by Logimag, are widely used in industries such as automotive, electronics, renewable energy, consumer goods, and more. Logimag’s bonded magnet manufacturer offer superior magnetic properties and reliability, ensuring that bonded neodymium magnet meet the demanding requirements of customers across various sectors.

Applications of Bonded Magnets

Bonded NdFeB magnets are used in a variety of applications, thanks to their versatility and unique properties. Some common applications include:

Automotive Industry

Bonded magnets play a crucial role in the automotive industry, where they are used in electric motors, sensors, actuators, and power steering systems. The strength and durability of Logimag’s bonded magnet manufacturer help ensure that these components perform reliably and efficiently in the harsh conditions of modern vehicles.

Consumer Electronics

Bonded magnets are essential components in consumer electronics, including speakers, hard drives, and headphones. Logimag’s bonded magnet manufacturer are used in these applications due to their compact size, high magnetic strength, and ability to deliver consistent performance.

Renewable Energy

In renewable energy applications such as wind turbines and solar panels, bonded magnets are used to generate power and increase efficiency. Logimag’s bonded magnet supplier high-performance bonded magnets provide the strength and stability needed for renewable energy systems, helping to drive the green energy revolution.

Medical Equipment

Bonded magnets are used in medical devices, such as MRI machines, hearing aids, and surgical instruments. Logimag’s bonded magnet supplier provide the precision and reliability required for these critical applications, ensuring that medical equipment operates with maximum accuracy and safety.

Aerospace

The aerospace industry relies on bonded magnets for various components, including actuators, motors, and sensors. Logimag’s bonded NdFeB magnet are designed to withstand the extreme conditions of aerospace environments, ensuring the continued reliability and performance of aircraft systems.

Why Bonded NdFeB Magnets?

Bonded NdFeB magnets offer several advantages over other types of magnets, making them an excellent choice for a wide range of applications. These include:

Flexibility in Design

Bonded NdFeB magnets can be molded into a variety of shapes and sizes, making them ideal for complex designs that require specific geometries.

Cost-Effectiveness

The bonded magnet manufacturer manufacturing process for bonded magnets is often more affordable than traditional sintered magnet production, making them a budget-friendly solution for many applications.

Lightweight

Bonded neodymium magnets tend to be lighter than other types of magnets, which is especially important in applications like automotive or aerospace where weight reduction is a key factor.

Magnetic Performance

Despite being lightweight, bonded magnets can offer excellent magnetic strength, making them suitable for demanding applications.

Why Choose Logimag Bonded NdFeB Magnet?

When it comes to choosing the right magnetic solution for your business, Logimag stands out as a leading provider of bonded NdFeB magnets. As an established magnet manufacturer, Logimag has consistently delivered high-quality products that meet the diverse needs of industries ranging from automotive to consumer electronics. Bonded NdFeB (Neodymium Iron Boron) magnets, also known as bonded rare earth magnets, offer several distinct advantages, making them ideal for various applications.

Exceptional Magnetic Strength

Logimag's bonded NdFeB magnets are renowned for their strong magnetic fields and high energy product. Neodymium magnets are considered the most powerful type of permanent magnet available today, and Logimag harnesses the full potential of this rare earth element. Bonded NdFeB magnets, in particular, combine the best of both worlds: the high magnetic strength of traditional sintered NdFeB magnets, and the flexibility and cost-effectiveness offered by the bonded magnet process. The magnetic strength of Logimag’s bonded NdFeB magnets ensures that they are perfect for applications where high-performance is crucial. These magnets offer excellent coercivity, which makes them resistant to demagnetization, even in high-temperature environments. Whether used in automotive components, sensors, or motors, these magnets perform reliably and consistently over time.

Customization and Flexibility

One of the key advantages of Logimag's bonded magnet manufacturer is their ability to be easily customized to meet the specific needs of each bonded magnet supplier client. Unlike sintered magnets, which are often produced in standard shapes and sizes, bonded magnets can be molded into a wide range of complex shapes and sizes. This ability to produce magnets with unique geometries makes them ideal for applications with limited space or unusual designs. At Logimag, customization is a priority, and the company offers tailored solutions to ensure the perfect fit for any project. Whether you need magnets with specific magnetic characteristics, sizes, or shapes, Logimag’s bonded magnet manufacturer experienced engineers and technicians will work closely with you to develop the optimal solution for your needs.

Cost-Effective Solution

Cost is often a major concern for businesses seeking magnetic solutions. Bonded NdFeB magnets from Logimag bonded magnet manufacturer offer an excellent cost-to-performance ratio, making them a budget-friendly option without compromising on quality. The manufacturing process for bonded magnets is more efficient compared to sintered magnets, which helps reduce production costs. Logimag’s bonded magnet manufacturer advanced technology and streamlined processes ensure that they can offer high-quality bonded NdFeB magnets at a competitive bonded magnet supplier price point. Moreover, the lightweight nature of bonded NdFeB magnets further reduces overall costs. These magnets are ideal for applications that require weight savings, such as automotive, aerospace, and renewable energy sectors, where reducing weight can lead to improved efficiency and reduced fuel consumption.

Superior Corrosion Resistance

One of the challenges with traditional NdFeB magnets is their susceptibility to corrosion when exposed to moisture or other environmental factors. However, Logimag’s bonded NdFeB magnets are designed with enhanced corrosion resistance. The bonding process involves encasing the magnetic powder in a protective layer, which helps shield the magnet from the elements. For applications where corrosion resistance is crucial, such as in marine environments or outdoor equipment, Logimag’s bonded NdFeB magnets provide a long-lasting and reliable solution. The corrosion resistance ensures that the magnets maintain their magnetic properties and functionality over time, reducing the need for frequent maintenance or replacement.

Versatility Across Industries

Logimag’s bonded NdFeB magnets are highly versatile and can be used across a wide range of industries and applications. Whether you are in the automotive, electronics, medical, renewable energy, or industrial sectors, Logimag bonded magnet supplier offers a solution that meets your specific requirements.

High Temperature Stability

While all magnets have certain limitations when it comes to temperature, Logimag’s bonded NdFeB magnets are designed to offer excellent temperature stability. These magnets perform well under a wide range of temperatures, making them suitable for applications that experience high heat or temperature fluctuations. Logimag’s bonded NdFeB magnets can withstand higher temperatures compared to traditional ferrite magnets, making them an excellent choice for industries such as automotive, aerospace, and energy production, where temperature stability is crucial to ensuring the longevity and reliability of the components.

Environmentally Friendly

Sustainability is increasingly becoming a priority for companies across the globe, and Logimag is committed to minimizing its environmental impact. The bonded magnet manufacturer production process for bonded NdFeB magnets involves responsible sourcing of raw materials, as well as adherence to strict environmental standards. By offering a more cost-effective and energy-efficient manufacturing process, Logimag helps reduce the carbon footprint associated with the production of magnets. In addition, Logimag ensures that its products are recyclable and safe for disposal, making them a more environmentally friendly choice compared to some other types of magnets.

Reliability and Consistency

When choosing a bonded magnet supplier, consistency and reliability are crucial. Logimag has built a reputation for delivering high-quality bonded NdFeB magnets with consistent magnetic properties and dimensional accuracy. The company’s ISO 9001-certified quality management system ensures that every bonded magnet supplier product meets rigorous quality standards before it reaches the bonded magnet supplier customer. Logimag’s bonded NdFeB magnets are manufactured using precise processes that result in magnets with predictable and stable magnetic performance. This reliability is vital for industries that require magnets to perform consistently over time, without significant degradation or failure.

Fast and Efficient Delivery

In today’s fast-paced business world, timely delivery is critical. Logimag understands the importance of quick turnaround times, and the company works hard to ensure that bonded magnet supplier customers receive their bonded NdFeB magnets on schedule. Whether you need small orders or large-scale production, Logimag is equipped to handle orders efficiently and ensure fast delivery times. With a reliable bonded magnet supplier supply chain and streamlined manufacturing processes, Logimag ensures that you get your bonded NdFeB magnets when you need them, without unnecessary delays.

The Importance of High-Quality Bonded Neodymium Magnets

High-quality bonded neodymium magnets are essential in a wide range of industries due to their strength, versatility, and cost-effectiveness. As one of the most powerful types of permanent magnets, bonded neodymium (NdFeB) magnets offer unique advantages that make them ideal for a variety of applications, including in the automotive, electronics, renewable energy, and medical sectors. When selecting a magnet supplier, it is critical to choose a provider, like Logimag bonded magnet manufacturer, that ensures the highest standards of quality in its bonded neodymium magnets.

Superior Magnetic Strength

One of the most significant advantages of high-quality bonded neodymium magnets is their powerful magnetic strength. Neodymium magnets, especially bonded ones, are known for their exceptionally high energy product. This translates to their ability to generate strong magnetic fields relative to their size, which makes them suitable for applications where space is limited but high magnetic force is required. Logimag, as a leading bonded magnet supplier, ensures that the magnets they produce consistently meet the highest standards of magnetic strength. This is particularly important in industries where compact and lightweight designs are essential but without compromising performance. Whether used in miniature motors, magnetic actuators, or sensors, high-quality bonded neodymium magnets provide the required magnetic force to ensure optimal functionality.

Improved Durability and Resistance to Demagnetization

High-quality bonded neodymium magnets, such as those provided by Logimag, have a high resistance to demagnetization. This means that even in extreme conditions or after extended use, the magnet will retain its magnetic properties over time, ensuring long-lasting performance. Neodymium magnets can be susceptible to demagnetization if exposed to high temperatures or strong opposing magnetic fields, but Logimag's quality assurance processes ensure that the bonded NdFeB magnets produced are resistant to these conditions. This is particularly important in industries like automotive or aerospace, where components are subjected to harsh environments. The superior resistance to demagnetization provided by high-quality bonded neodymium magnets ensures that the performance of critical components remains stable throughout their lifespan, reducing the need for costly repairs or replacements.

Customization Options for Specific Applications

High-quality bonded neodymium magnets offer a significant advantage when it comes to customization. The bonded magnet manufacturer process allows for the creation of magnets in a wide range of shapes, sizes, and designs that would be difficult to achieve using traditional sintering methods. This flexibility makes them ideal for applications with specific design or performance requirements. Logimag bonded magnet manufacturer is committed to offering a broad range of customization options to meet the unique needs of each bonded magnet supplier client. The bonding process involves mixing magnetic powders with a polymer binder, which can be molded into virtually any shape or size. This allows manufacturers to create magnets with intricate geometries that can be tailored for specific devices or applications. The ability to customize bonded neodymium magnets ensures that industries can develop highly efficient, space-saving, and innovative solutions without sacrificing performance.

Cost-Effectiveness and High Performance

While neodymium magnets are generally considered high-performance components, bonded neodymium magnets are a more cost-effective alternative compared to traditional sintered magnets. The bonding process not only enables the production of magnets in complex shapes but also helps reduce the overall cost of manufacturing. Logimag’s high-quality bonded neodymium magnets offer a great cost-to-performance ratio, providing industries with a budget-friendly option for magnetic solutions without compromising on strength or durability. Their ability to be produced in bulk at competitive bonded magnet supplier prices makes them an attractive choice for companies looking for high-performance magnets without exceeding their budgets. Moreover, the cost-effectiveness of bonded neodymium magnets extends beyond the initial bonded magnet supplier purchase price. Their long lifespan, high resistance to demagnetization, and versatility make them an excellent investment for businesses, reducing the need for frequent replacements and contributing to lower overall maintenance costs.

Environmental Benefits of Bonded Magnets

Another reason why high-quality bonded neodymium magnets are so important is their relatively low environmental impact. Unlike sintered magnets, which are produced at extremely high temperatures and energy levels, bonded NdFeB magnets are manufactured using a more energy-efficient process. The bonding process allows the magnets to be produced at lower temperatures, reducing energy consumption and greenhouse gas emissions. Logimag's commitment to environmentally friendly manufacturing practices ensures that their bonded neodymium magnets have a minimal environmental footprint. This aligns with the growing demand for sustainable bonded NdFeB magnet products in various industries, where businesses are under increasing pressure to reduce their carbon footprint and adopt greener practices.

Superior Corrosion Resistance

One of the challenges associated with neodymium magnets is their susceptibility to corrosion when exposed to moisture or harsh environmental conditions. However, high-quality bonded neodymium magnets often have better corrosion resistance compared to sintered magnets. The polymer binder used in the bonding process can provide a protective layer around the magnetic particles, helping to shield them from the effects of moisture and air. Logimag's high-quality bonded neodymium magnets are designed with excellent corrosion resistance, making them ideal for use in applications that require long-term exposure to humidity, seawater, or other corrosive environments. Whether in marine equipment, outdoor machinery, or industrial settings, Logimag’s bonded NdFeB magnets ensure reliable performance without degradation over time.

Wide Temperature Range Performance

While bonded neodymium magnets are not as resistant to high temperatures as sintered magnets, high-quality bonded neodymium magnets from Logimag still perform well in a wide range of temperatures. These magnets maintain their magnetic strength and stability within certain temperature limits, making them suitable for many applications that experience temperature fluctuations. Logimag ensures that their bonded neodymium magnets are optimized for temperature stability, providing dependable performance in environments with varying heat conditions. Industries that rely on high-temperature processes, such as automotive or renewable energy, can trust Logimag to deliver bonded NdFeB magnets that work reliably in challenging thermal environments.

Long-Term Cost Savings

While high-quality bonded neodymium magnets may have a slightly higher initial cost compared to other types of magnets, their long-term performance and durability make them a worthwhile investment. Due to their resistance to demagnetization, corrosion, and wear, these magnets require fewer replacements and maintenance over their lifespan. Logimag's high-quality bonded neodymium magnets provide industries with long-term cost savings by ensuring that the magnets retain their magnetic properties for extended periods of time. This reduces bonded magnet manufacturer operational costs and downtime, contributing to the overall efficiency and profitability of a business.

Bonded NdFeB Magnet Material Information

Bonded NdFeB (Neodymium-Iron-Boron) magnets are one of the most popular types of permanent magnets in modern industries due to their impressive magnetic properties, versatility, and cost-effectiveness. These magnets are made using advanced manufacturing techniques such as injection molding or hot pressing, which allows them to be molded into complex shapes and customized to meet the specific needs of various applications. Logimag, a leading magnet manufacturer, specializes in producing high-quality bonded NdFeB magnets with superior properties that are suitable for a wide range of industries, including automotive, electronics, medical devices, and renewable energy systems.

-Produced by Injection Molding or Hot Pressing with Mixture of Ferrite/Rare Earth Magnet Powder & Polymer Binder

-Complex Shapes Possible (Gears, Thin Rings, etc)

-Reduce Assembly Time - Mold or Insert Components into Magnets during Manufacturing Process

-Good Resistance to Chips & Corrosions

-Excellent Corrosion Resistance

-Magnetize Entirely or in Segments

-Maximum Working Temperature 200℃ (Injection Bonded) / 120℃ (Compression Bonded)

FAQ about Logimag for Bonded Magnet Manufacturer, Bonded Magnet Supplier, Bonded Neodymium Magnet and Bonded NdFeB Magnet

1. What sets Logimag apart as a bonded magnet manufacturer?

Logimag stands out as a leading bonded magnet manufacturer due to its advanced production techniques, including injection molding and compression molding. These methods allow for intricate shapes and high-performance magnets. Our bonded magnet manufacturer expertise in producing bonded neodymium magnets ensures high-quality products that are reliable and cost-effective. The bonded magnet manufacturer focus on quality control, customizable solutions, and excellent customer service makes them a preferred bonded magnet supplier in industries such as automotive, electronics, and renewable energy.

2. Why should I choose Logimag as my bonded neodymium magnet supplier?

Logimag is an ideal choice for bonded neodymium magnet supply due to its extensive experience and commitment to producing high-performance magnets. Our use of state-of-the-art molding techniques allows for complex shapes while maintaining magnetic strength and durability. Logimag provides customized solutions for various applications, ensuring that every product meets specific bonded magnet supplier customer needs. Additionally, we offer competitive bonded magnet supplier pricing, fast lead times, and excellent technical support, making us as trusted bonded magnet supplier in diverse sectors, including electronics, automotive, and renewable energy.

3. What are the benefits of bonded NdFeB magnets over sintered magnets?

Bonded NdFeB magnets offer several advantages over sintered magnets, such as flexibility in design. They can be molded into complex shapes like gears or rings, unlike sintered magnets, which are more limited in form. Bonded magnets are also more durable and resistant to mechanical stress. They offer higher corrosion resistance due to the polymer binder and have better performance in certain applications. Additionally, bonded magnets can be magnetized in segments, giving greater control over their properties, making them suitable for various industries like automotive and consumer electronics.

4. How does Logimag ensure the quality of its bonded magnets?

Logimag ensures the quality of its bonded neodymium magnets by using rigorous testing at each production stage. From material selection to final inspection, every bonded neodymium magnet undergoes thorough checks for magnetic strength, coercivity, and temperature stability. We use advanced testing methods and adhere to ISO quality standards, ensuring reliable and consistent products. Our commitment to quality is demonstrated use of high-grade materials and state-of-the-art manufacturing processes, which guarantee that every bonded magnet is durable, performs optimally, and meets customer specifications.

5. What industries benefit from Logimag’s bonded NdFeB magnets?

Logimag’s bonded NdFeB magnets are used across various industries, including automotive, electronics, and renewable energy. In automotive applications, they power components like motors and sensors. In electronics, they are used in hard drives, speakers, and sensors. The renewable energy sector also relies on these magnets for wind turbine generators and motors. Their versatility in design and high-performance capabilities make them suitable for numerous applications, delivering consistent reliability and efficiency across industries that demand precision and durability.